DISCOVER THE UNIQUE ADVANTAGES OF

ATMOSPHERIC PLASMA SURFACE TREATMENT

ONE TOOL

Replaces Multiple Process Steps

Compare to Traditional Surface Prep Methods

(Click icons below)

ENVIRONMENTAL IMPACT REDUCTION

Plionyx operates without solvents, eliminating harmful environmental effects. It replaces or enhances abrasive methods like blasting, grinding, and chemical baths, reducing waste and the need for cleanup.

ENHANCED SAFETY

The handheld, ergonomic design emits no dangerous light or fumes, minimizing operator fatigue and eliminating vibrational impact.

TIME AND COST SAVINGS

The system requires lower capital investment, reduces downtime, and eliminates the need for extensive setup or containment procedures. Only input in air and electricity. Save on purchasing and disposing of media and solvents.

REDUCE PROCESS STEPS

With deployment in under five minutes and evidenced over 90% labor savings. Because the system removes, cleans and activates in one pass the process is completed at one location.

Success Stories

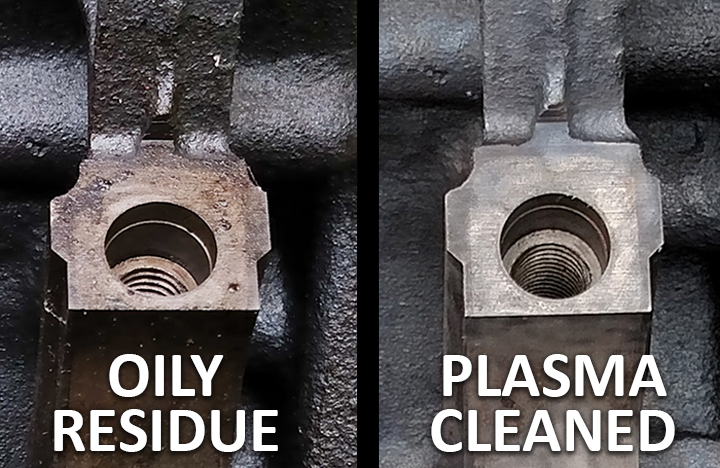

Surface Cleaning That Performs Under Pressure

Improving Laser Welding Efficiency on Hydraulic System Parts

When an industry-leading manufacturer needed to improve their process of laser welding essential parts for the safe operation of heavy-duty vehicles, they turned to the powerful surface preparation advantages of Plionyx…. Read the story

Driven to Excel

An automotive supplier seeks a superior solution for adhesive bonding

For manufacturers in the automotive industry, it’s a race to evolve faster than the competition. Their production processes must continually get faster, better, and greener in order to compete in today’s market…. Read the Story

Conquering Sticky Situations

Plionyx slashes downtime for surface cleaning in paper and textile converting applications

Two major players in the converting industry—who provide specialized equipment for paper mills and textile factories—are using Plionyx atmospheric plasma systems to clean and protect essential mechanical components that keep production rolling at their sites…. Read the Story

What this Tech Does

REMOVES COATINGS, CLEANS AND IMPROVES ADHESION TO ACHIEVE LONGER AND STRONGER BONDS

hOW THIS TECH DOES IT

A plasma-treated surface will result in a stronger bond due to the addition of reactive chemical species to the surface.

ENHANCE MOLECULAR ATTRACTION

The delivery of these species forms a linking site, which increases the surface energy and facilitates the spread of the coating across the material. This results in a larger contact area between the material and the coating, which both enhances bond strength and improves corrosion resistance.

HARNESSING ATMOSPHERIC PLASMA

Atmospheric pressure plasma is formed at ambient temperature and pressure in a specific gas or gas mixtures such as air, carbon dioxide, argon, helium, water vapor, etc. The energy applied to these gases causes a “breakdown”, where gas molecules are ionized resulting in free electrons.

These electrons then become energetic due to the energy applied and react with the surrounding gas to form reactive chemical species to establish a stronger bond.

The results of Dolly Pull test: solvent-wiped vs Plasma treated.

Paint pulls away from steel surface that was solvent-wiped before painting with significantly less force than that of the plasma-treated surface.