Industry Solutions

Featured Industries

The PLIONYX System: A Superior Alternative for Surface Preparation

A universal job responsibility of industrial production managers is keeping company machinery in peak working condition. This effort requires both a substantial portion of limited financial resources and an ongoing time commitment. Despite their negative impact on the bottom line, these expenditures have always been accepted as an unavoidable cost of doing business. Fortunately, the PLIONYX 3-in-1 Portable Surface Preparation System enables end users to easily mitigate many of these existing challenges.

SIMPLIFIED EFFORTS WITH NUMEROUS BENEFITS

The advantages of a PLIONYX system are significant when compared to the mechanical, chemical, and media blasting techniques traditionally used for surface modification and treatment. Those charged with equipment upkeep will immediately benefit once they begin using this superior approach, achieving their desired results more quickly and easily, at a lower cost, and without any harmful environmental impact.

SURFACE TREATMENT WITHOUT THE DOWNSIDE

Throughout their careers, Environment, Health, and Safety (EHS) managers and production managers alike have come to accept the many drawbacks associated with the various approaches to surface preparation and the limitations associated with their required tools.

As an example, the use of solvents has long been accepted as a necessary evil simply because there haven’t been any viable alternatives. When one accounts for the repeat purchases, the never-ending task of managing storage, the dangerous/toxic nature of the materials, and all of the time and effort which is required for clean up and disposal, it becomes clear the downsides of this approach are significant. Thanks to the PLIONYX system, the need for this particular method has been dramatically reduced, if not eliminated entirely.

TWO DEPLOYMENT OPTIONS FOR IMPROVED FLEXIBILITY

The PLIONYX Surface Preparation System is available in a handheld version, ideal for on-the-fly applications around the shop or in the field, or in a mountable/robotic version designed specifically for situations where a precise, automated solution is required.AUTOMOTIVE MANUFACTURING

The PLIONYX system is the ideal tool for situations where inline surface treatment is required to foster enhanced bonding of components common to automotive manufacturing. It is the most reliable surface preparation technique prior to applying protective coatings. The variety of coatings and adhesives utilized in these types of applications include paints, epoxies, polyurethanes, powder coats, e-coats, polyureas, and more.

Process speed is critical to a profitable operation. The PLIONYX system provides an order of magnitude faster result than any other option currently available. Additionally, our tool makes bonding of low surface energy materials like polypropylene, polyethylene and various fluoropolymers (Teflon) possible.

CONVERTING INDUSTRY

In converting processes, a clean surface is required to assure the highest quality finished products. Due to the physical nature of the process where the equipment is in constant contact with the product, any contaminants on the roller will be transferred to the product surface and cause reduced quality and yield. The PLIONYX system excels at maintaining surface cleanliness inline during production, or offline during periodic maintenance.

When doing needed routine maintenance or repair, the PLIONYX system will facilitate the quick and easy removal of various forms of build-up, such as inks, adhesives, or other contaminants. It will also allow for the efficient resurfacing of rubber rollers and cleaning of anilox rollers, negating the need for toxic wet chemicals and removing potential harmful emissions from your work environment, making for a safe and healthier workplace. Whether you are manufacturing packaging, clothing, roofing materials, labels, paper goods, or any other finished product, your end result will be assured when you’ve maintained your equipment with the PLIONYX system.

INDUSTRIAL MAINTENANCE

Whether undertaking maintenance efforts around a factory/shop or making repairs on the fly in the field, having the flexibility of a mobile surface preparation system is critically important. Difficult to reach work areas preclude using large and heavy equipment and complicate any necessary containment efforts. As an example, neither laser ablation or media blasting are practical/feasible for use on structures such as bridges or wind towers, especially in rope access situations. Weighing in at less than 30 lbs, the PLIONYX system, however, can go anywhere its operator can.

In addition to its quick set-up and portability, the precise nature of the APS tool makes it more widely applicable than other options. It can be used on complex geometries that are typically very difficult or even impossible to treat effectively. Whether users are removing paint from bolt threads or getting down into the recesses of a crack, the PLIONYX system’s powerful and fluid-like plume makes it the perfect solution, especially when contending with hard-to-reach areas.

METAL FABRICATION

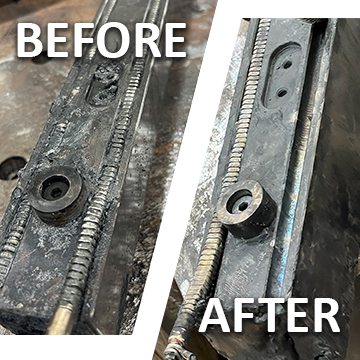

To achieve a high-quality weld, it is necessary to first create the cleanest surfaces possible, which ensures the best final results. Whether you are removing mill oil, carbon deposits, Cosmoline (or other corrosion inhibitors), a clean surface is simple to produce when using the PLIONYX Surface Preparation System.

When surface preparation must be done prior to applying coatings or adhesives, or when performing metal-to-metal bonding (adhesive welds), the final results are longer-lasting and stronger when utilizing the PLIONYX system.

Non-destructive inspection

& testing (NDI/NDT)

When performing an NDI/NDT process, the removal of some form of a coating or contaminant is often necessary. The PLIONYX system accomplishes this by taking advantage of the “fluid-like” nature of plasma, which allows it to flow around convoluted surfaces that are otherwise challenging to clean efficiently. This also effectively eliminates the need for chemical and/or mechanical techniques, reducing waste in the process.

By increasing the surface energy within defects, plasma significantly improves the wetting ability of the penetrant used, allowing it to better flow into defects for improved detection. Additionally, the PLIONYX tool does not drive material into the flaw, a liability of other approaches, but rather it etches away materials that may be masking the existence of miniscule flaws, serving to enhance the evaluation. These added benefits effectively eliminate the need for multiple rounds of cleaning and retesting.

PLASTICS & RUBBER MOLDING

By taking advantage of the PLIONYX surface preparation system, users will dramatically reduce any chance of expensive machinery damage by entirely eliminating the physical contact with the metal of the mold typical of manual cleaning techniques.

Additionally, having systems on hand enables users to do regularly scheduled touchup treatments of their equipment in order to keep it in good overall working condition. This means that the machines will no longer have to be taken offline, which of course creates extended downtime and erodes profitability.

As another added benefit, the fluid-like nature of the plasma plume allows it to quickly and easily remove accumulated residual materials from hot runners and tight spaces like mold channels and cavities. As a welcome result, the jobs which previously were the most challenging and time-consuming are no longer an issue.

EXAMPLE Process Improvements

Clean

- Rust inhibitor removal

- Machining coolant & cutting fluid

- Tips, nozzles & mixers

- Mold & stamping release agents

- NDI/NDT inspection cleaning of dye penetrant

PREPARe

- Improve bonding of dissimilar materials

- Promote gasket adhesion

- Post weld surface preparation

- Increase bond strength of coatings, sealants & adhesives

- Enhanced wettability

RemovE

- Expose surfaces & welds for inspection

- Mold flashing removal

- Rework painted, powder coated & e-coated parts

- Foam & rubber gasket removal

- Removes polyurethane, epoxy & polyimide adhesives

Proven Success Treating a Wide Variety of Coatings, Sealants, and Substrates

Coatings Removed

- Acrylics

- Alkyds

- Latex

- Epoxies

- Polyurethanes

- Polyesters

- Powder Coats

- Silicone / Polysiloxanes

- Coal-Tar Epoxy

- Ultra High Solid Coatings

Sealants Removed

- Elastomeric

- Caulking

- Polysulfide

- Polyether

- Butyls

- Acrylics

- Rubber

- Silicones

- Polyurethane

- Tape(s)

Substrates Treated

- Aluminum Alloys

- Magnesium Alloys

- Steel Alloys

- Titanium Alloys

- Plastics

- Carbon Fiber

- GRP/Fiberglass

- Composites

- Concrete

- Ceramics