The Plasma Advantage

A Superior Alternative

- Solvent-free process eliminates negative environmental impact

- Replaces abrasive blasting, grinding and chemical baths

- No tedious clean up or costly disposal of blast media, sanding, or debris

- No dangerous light emissions or fumes

- Hand-held, ergonomic precision pen

- Light-weight pen enables significantly longer usage without fatigue

- No vibrational impact on operators

- Save on the purchase and disposal of various media and solvents

- Lower capital investment and reduce revenue lost to downtime

- No time intensive tarping or containment set-up or tear down

- Demonstrated over 90% labor savings compared to traditional methods

- Deploys in less than 5 minutes

- Simple to operate; no adjustments

CLEAN

without waste

without waste

POOR SURFACE PREPARATION IS THE #1 REASON FOR COATING SYSTEMS FAILURE

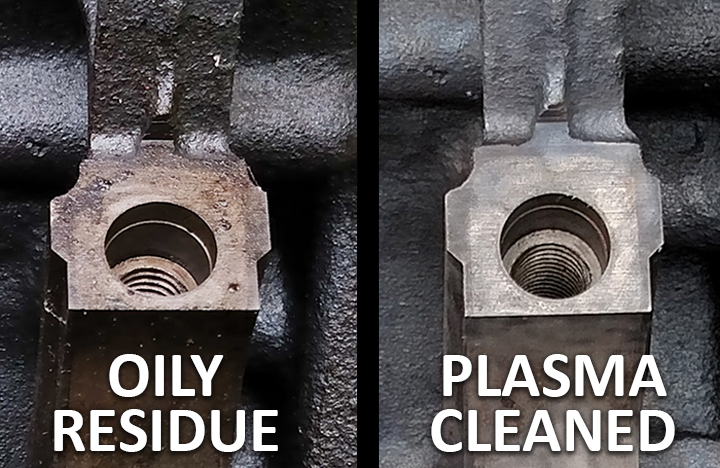

Surface cleaning performed with an Atmospheric Plasma Solutions system is driven by the dry chemical etching effect of the plasma-generated reactive species.

The cleanliness of the uppermost molecular layers of a surface can drastically impact the quality of an adhesive bond. Even trace amounts of oil, grease, or fingerprints can result in changes to the surface that can cause defects in the coating. This then leads to poor adhesion and/or the potential for a coating failure.

When treated by a PLIONYX system, any contamination is immediately vaporized and blown off by compressed air, resulting in a pristine surface. Since there are no added chemicals, no residue is left behind on the surface. Plasma treatments unlock the chemical bonding sites of the surface for superior bonding and adhesion, but they do not damage or remove any material from the original substrate.

CHEMICAL AND MEDIA FREE CLEANING OF THE SURFACE

The PLIONYX system provides for the efficient cleaning of surfaces due the rapid reactions between plasma species and contaminants. Plasma is utilized as either a replacement for, or in conjunction with, traditional media blasting methods of surface cleaning, including: baking soda, dry ice, grit, and plastic media (PMB). The need for solvents is largely negated, which saves the cost of replenishment, removes a threat to applicators’ health, and eliminates the negative environmental impact of the waste stream.

AVOID COSTLY CONTAINMENT & CLEAN UP

The use of media blasting methods often requires the work zone to be shut down and tarped off, which prohibits other activity in the surrounding areas, requires additional supplies, and takes valuable time away from the maintenance efforts. Not only does the set-up prolong the process, so does the associated clean-up of the spent media, which is both challenging and tedious. Once that is complete, there is still another stage of the procedure as the collected waste has to be properly disposed of, which comes with yet more added expense and oversight. When utilizing the PLIONYX System, none of this is necessary.

Discover a new way to create

a consistently cleaner surface.

PREPARE

for better adhesion

for better adhesion

ACHIEVE LONGER & STRONGER BONDS

A plasma-treated surface will result in a stronger bond due to the addition of reactive chemical species to the surface.

Enhance molecular attraction

The delivery of these species forms a linking site, which increases the surface energy and facilitates the spread of the coating across the material. This results in a larger contact area between the material and the coating, which both enhances bond strength and improves corrosion resistance.

Prepare surfaces for better adhesion.

REMOVE

with precision

with precision

IDEAL FOR USE ON EVEN THE MOST DIFFICULT-TO-TREAT IRREGULAR SURFACES

APS systems treat the complete surface, including any cracks, crevices, or profile valleys. The plasma flows like a fluid and removes coatings covering any shapes or complex geometries, getting into tight and/or confined spaces, which other tools cannot.

TREAT SURFACES WITHOUT DAMAGING THE SUBSTRATE

The PLIONYX Surface Preparation System removes coatings while preserving the surface underneath and does not change the profile or material properties of the metal. The system is based on proven and patented technology. The plasma transforms up to 100% of the coating into harmless gases, carbon dioxide and water vapor, while the rest is blown away as dust.

A better way to remove coatings.

Non-Thermal Plasma

Solids → Liquids → Gases → Plasma. This fourth state of matter’s properties are dependent upon the chemical composition of the materials which form it.

PLASMA IN EVERYDAY LIFE

In everyday life, people observe plasma in the aurorae, lightning, fluorescent light bulbs and use plasma through their spark plugs to start their car.

Each of these applications have a plasma that is different due to the composition, pressure, and amount of energy applied. Plasma applications are typically separated by pressure (low, atmospheric, and high) and their thermodynamic properties (thermal and non-thermal).

Examples of low-pressure plasma applications are semiconductor wafer cleaning and fluorescent light bulbs. High pressure plasmas are studied for hypersonic vehicles, space craft, and fusion energy.

In the past 30 years, atmospheric pressure plasmas have gained interest for their use in applications similar to low pressure applications, but without the expensive equipment required to maintain a low pressure environment.

HARNESSING ATMOSPHERIC PLASMA

Atmospheric pressure plasma is formed at ambient temperature and pressure in a specific gas or gas mixtures such as air, carbon dioxide, argon, helium, water vapor, etc. The energy applied to these gases causes a “breakdown”, where gas molecules are ionized resulting in free electrons. These electrons then become energetic due to the energy applied and react with the surrounding gas to form reactive chemical species.